Emulsified fuels: Cleaner & More Efficient

Fossil fuel emulsions

Fluids that do not dissolve in each other can still be combined by forming an emulsion. This involves distributing droplets of one throughout the other. Because emulsions are unstable and eventually separate back out, chemicals (surfactants) are also added to help hold them together.

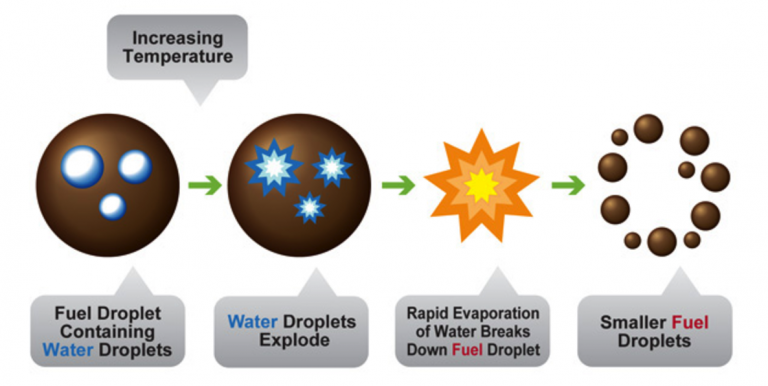

An emulsion takes on many of the characteristics of the outer liquid. so a water in oil emulsion will behave like a fuel because the oil is on the outside. However on heating the water droplets vaporise, better atomising the oil, giving more complete combustion. Emulsified fuels are unique in that they reduce both NOx and particulate emissions while improving efficiency.

Provided the volume of use is high the efficiency gains will exceed the cost of the emulsifier system and give net savings.

So these systems suit situations where you use Fuel Oil in significant quantities e.g. marine engines, industrial burners, or where emissions are a problem e.g. in mines.

Applications typically need in-line blenders feeding a buffer tank, although smaller industrial burners could use a batch blender. BFSNZ with AET and InterIslander line ran a trial on an auxiliary generator on the Arahura at wharf, followed by a 6 month trial at sea. This gave 3-5% fuels savings and reductions in pollutants. The Executive Summaries of the independent test reports are available here (136KB).

Through AET we offer a range of blend units and surfactants to meet various applications.

Biofuel emulsions

Despite the various benefits, a problem with biodiesel is the NOx emissions. Compared with USEPA approved diesel fuel, 100% biodiesel emits half the particulates (PM) and CO, no SO2, and 25% of the CO2, but the NOx emissions increase by 10%.

Emulsifying the biodiesel with small quantities of water can eliminate this increase allowing the fuels to meet regulatory standards. Further if the biofuel is from renewable sources then these reductions will directly contribute to reducing GHGs.

A further potential use of emulsions with biofuels is to help manage the water content and stabilise less refined biocrudes and manage their acidity. Creating an emulsion of a biocrude in a mineral oil or even a refined biofuel is potentially a low cost way of introducing biofuels into heavy engines.

If you are looking for emulsified fuel solutions contact Leigh Ramsey MD.